Builders would agree that when given the choice of using manufactured roof trusses rather than building the roof on site, manufactured trusses save time, money, and headaches during the building process.

Integrity Building Products believes this build efficiency should also apply to walls. Traditional wall framing construction relies on the trade contractors to assemble all the pieces on the job site. Though the builder can still ensure a high-quality home, making sure each wall unit is built consistently and according to the plans can be difficult and time consuming. Bad weather, scheduling conflicts, construction errors and maintaining a qualified labor force can all lead to work delays or expensive rework.

With precision prefabricated wall panels from Integrity Building Products, our customers save time and money on the job site. Our wall panels are quicker and easier to install than traditional on-site framing. With a reduced requirement for skilled labour (compared to traditional framing), builders benefit from the ability to more easily scale up and down to align production capacity with market demand. The panels also deliver a 10-15% reduction in lumber waste, while also reducing change orders and on-site material management risks, including theft.

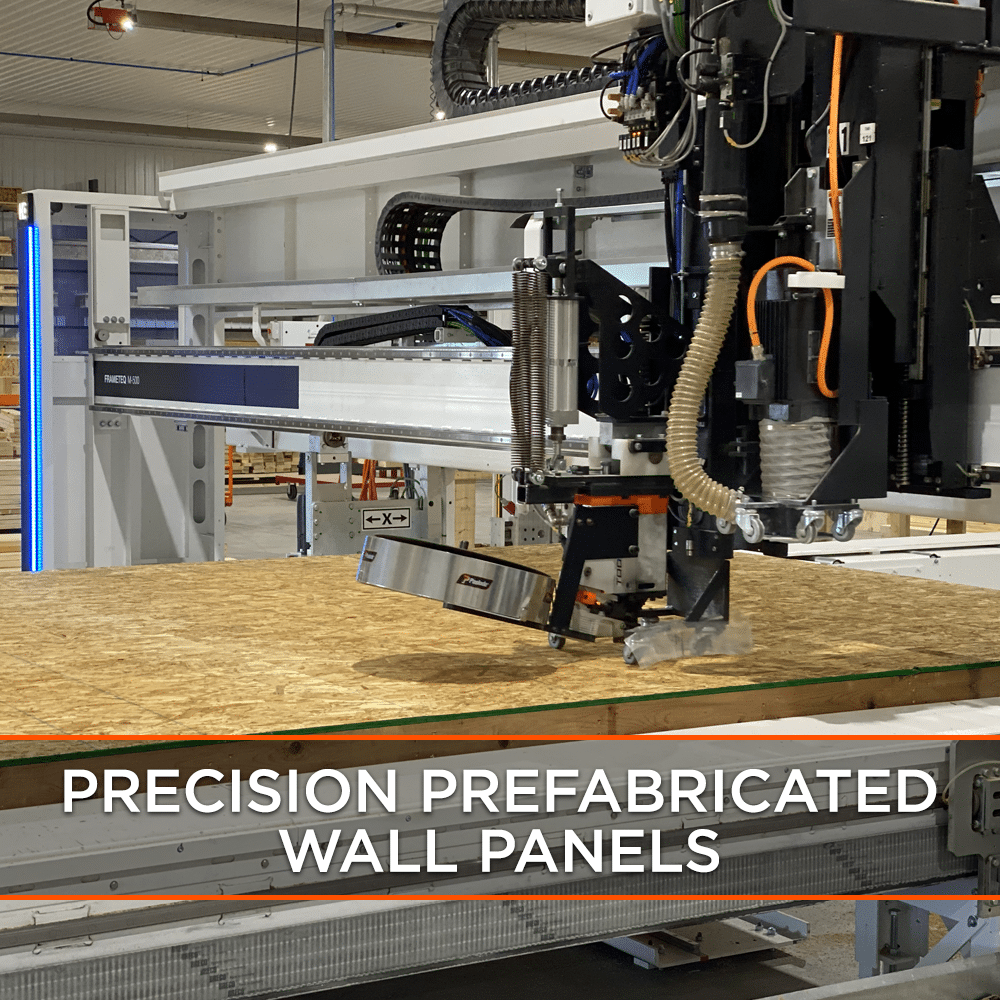

Our wall panels are designed and built using specialty software and precision technology. We have invested in the right equipment, software, and skilled staff to produce a high quality and consistent product.

Prefabricated wall panels are custom designed with MiTek software. These design files are directly integrated with MiTek’s Hornet Saw. The Hornet Saw is a fully automated cut saw that also labels every part of the wall panel. This level of precision detail and automation enables our team to prepare the materials faster, more accurately and consistently, and while optimizing materials to reduce waste. .

When all elements of the wall panel have been cut and labeled, they are moved to the WeinmannWall System Machine from Homag. The Weinmann is slightly larger than an assembly work table but combines processes for wall production and the processing of sheathing on a single workstation. Utilizing one skilled operator, we can produce a prefabricated wall panel every 10 minutes. All processes are completed within our assembly plant, ensuring consistency of output and weatherproof handling, ensuring reliable supply and a top quality product.

After the wall units are built, they are labeled for assembly and shipped directly to our customer’s job site. When the builder is ready to install the wall panels, they simply follow the installation and assembly procedures defined by the factory specifications.

Like manufactured roof trusses, Integrity Building Products precision prefabricated wall panels provide builders with the opportunity to gain a competitive edge, higher profit margins and faster cycle times for construction.