Building the Future:

Integrity Building Products Commitment to Innovation

The home building industry is being defined by its ability to innovate, modernize and revolutionize its methodologies and practices. Builders need to move quickly to maintain their competitive advantage. Integrity Building Products is committed to innovation and working with its partners to find new solutions to their business challenges.

Never Stopping at Good Enough

Integrity’s fundamental belief in never stopping at good enough is a driving force in the company’s adoption of innovative tools and processes. Integrity Building Products started in earnest in 2012, supplying building materials to Integrity Post Structures and the general public on a small scale. “Initially, Integrity Building Products was a supporting player,” explains Scott Myer, Chief Operations Officer of Integrity Group and Business Unit Leader of Integrity Building Products. “Our primary focus was to procure materials for the post-structure side of our business. But, as with all things at Integrity, we were driven to do more. We wanted to offer more, to provide greater services and value to the construction industry.”

Integrity Building Products initially entered the homebuilding market by supplying framing materials to Calbridge. “Based on our experience with Calbridge we continued to evolve our business, creating new processes, growing our team and expanding our client base to more single and multi-family homebuilders. We have grown to become a true partner with the builder community in Calgary,” explains Scott.

Evolution of Design & Estimating

As the number of customers and projects grew, the scope of operations also grew. Mike Boon, Design & Estimating Manager for Integrity Building Products has been involved in a lot of that growth. “The team grew quickly, and we needed a better way to integrate design, engineering and estimating,” explains Mike. “We needed to evolve our processes and our tools to meet the demand. A big breakthrough was when we started using MiTek software.”

Initially, Integrity used MiTek to complete estimating and material takeoffs for dimensional lumber. As Integrity Building Products grew, the team expanded its use of the tool to include the design and estimating of entire homes with multiple building products, such as floor systems and prefabricated wall panels. “MiTek is designed to evolve with our customers,” explains Kirk Wyss, MiTek District Sales Manager for BC, Alberta & Saskatchewan. “It’s an open source software, meaning users can update and add to the code, making it what they need it to be.”

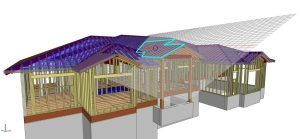

As Integrity customized the MiTek software to meet their business needs, the scope of work performed within the structural engineering software increased. “The opportunity to evolve with MiTek is expansive,” explains Mike, “but the real benefit is an increased ability to collaborate with our customers. MiTek Viewer enables us to build 3D models of homes, making it easier to communicate with our customer’s design team and site crew. Using MiTek, we can better integrate with our customers’ digital files, reducing errors.”

Mike and his team were able to use MiTek to help Cedarglen Homes find a solution to some common construction challenges including inaccurate estimating, inventory control and material waste. Pretum Narang, Purchasing and Estimating Manager at Cedarglen Homes, was looking for a new way to manage these challenges. “Our team felt strongly that these challenges could be overcome if data sharing with our vendors was more seamless. We challenged Integrity to develop a system where we could improve collaboration with design files, and they came through for us.”

Integrity Building Products likes to apply its passion for innovation when solving problems for their homebuilding partners. “Mike Boon and his design team are a driving force in pushing the boundaries of our MiTek software and its functionality,” adds Kirk.

Solving Industry Challenges with Innovative Products

Over the past decade, Integrity Building Products has become a reliable partner to Calbridge. When Calbridge faced the challenge of labour shortages and falling behind in their build schedule, they came to Integrity for a solution.

Framing with prefabricated wall panels in single-family residential construction was not widely done at this point. A few multi-family builders were working with Integrity Building Products to supply this manufactured component, while single-family builders were still relying primarily on stick framing. “We knew prefabricated wall panels could be a solution for Calbridge. It would allow them to build more homes with less labour,” explains Scott.

Prefab wall panels proved to be the answer Calbridge was looking for. “Converting a portion of their homes to wall panels was very successful, with Calbridge meeting their obligations to their home buyers,” Scott explains. “This innovative solution resulted in future expansion of their use of wall panels into more of Calbridge’s single-family home construction.”

Commitment to Continuous Innovation

Integrity Building Products was built on a commitment to innovation. The team has redefined how a building product manufacturer and supplier utilizes technology to solve business problems. “Working at Integrity has always been exciting. We are constantly changing, and thinking outside the box,” explains Mike. “Our commitment to innovation, including tools like MiTek, helps provide Integrity and our customers a competitive advantage.”