In the construction world, an old adage often rings true: “If it ain’t broke, don’t fix it.” Post-frame construction, a method dating back centuries, is no different. However, when Jerry Myer, founder of Integrity Post Structures, embarked on his journey 15 years ago, he carried a different belief – a belief that the status quo could be challenged and improved upon. This mindset gave birth to what is now known as the “Integrity Difference.”

The Integrity Difference is proof of Integrity Post Structures’ commitment to construction excellence and industry leadership. It proves that there is value in performing beyond “good enough” and instead, building better and stronger structures, even when it may not seem necessary.

Innovative Products

“I saw a need for better-built buildings – buildings that would last longer, stand stronger, and add greater value for our customers,” says Jerry. This need is the driving force behind Integrity Post Structures. “Post-frame construction is not new, but there were some challenges with this form of construction that I felt we could solve for our customers,” added Jerry.

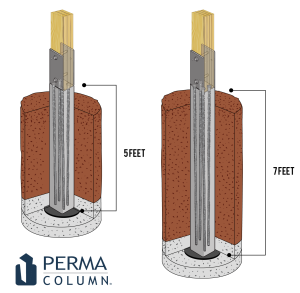

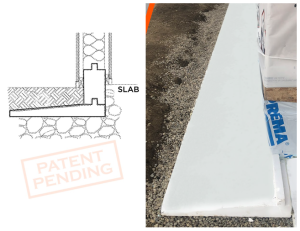

A centuries-old challenge with post-frame construction is that wood in the ground rots, eventually making the foundation of older post-frame buildings unstable. “Sometimes this makes a potential customer think twice about building a post-frame building,” explains Jerry. “A customer challenged me to find an alternative to the wood foundation and that initiated my research into alternative materials.”

Jerry reached out to Perma-Column®, a small materials manufacturer in Indiana, about utilizing their patented steel bracket and pre-cast concrete foundation system in Integrity’s post-frame buildings. “We built a relationship with Perma-Column and became the exclusive distributor in Western Canada,” explains Jerry. “Through this partnership, we were able to solve a common challenge for post-frame construction while also adding value for our customers.”

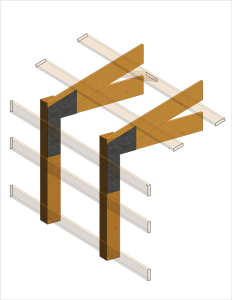

Another common building risk across the prairie provinces is our heavy winds. “You just can’t avoid the winds out here,” says Jason Murrell, an Integrity post-frame sales representative who’s been lending expertise to customers for over 10 years. High winds can cause a building to lean, or even fail, if not mitigated properly. “Heavy, consistent winds can cause a tall, large machine shed, which is one of the most common types of buildings we build, to lean. A lean of even a couple of inches can cause huge problems, including door jams,” explains Jason.

To solve this problem, Jerry and Integrity’s R&D team developed the Storm Bracket, a proprietary building component that strengthens the connection between the roof truss and the post. “We found with the Storm Bracket the building is better able to deflect the wind and we saw a significant increase in the strength of the building,” explains Jerry.

The Integrity Difference isn’t wholly defined by the materials and innovation in construction, it is also defined by the attitude that we do better because it’s the right thing to do. “We don’t have to build with better materials, like the Storm Bracket or Perma-Columns,” explains Jason. “Farmers have been building simple post-frame buildings using the same materials and construction methodology for centuries. But today’s customers appreciate the durability of these improved materials. They appreciate how they strengthen their building, protecting their investment in both the building and the valuable assets inside. Integrity didn’t need to evolve the construction method, but we did it anyway.”

A Commitment to Building Better

This commitment to continually innovate and improve post-frame buildings extends to every facet of construction, including design and engineering. “We were one of the first post-frame construction companies to offer engineered drawings as a standard part of our package,” explains Jerry. “Even though an engineered building wasn’t common practice for agriculture buildings when we started Integrity Post Structures, we chose to offer this service so our customers knew we were providing a high-quality product we could stand behind.”

While proof of engineering is a requirement for structures requiring a building permit, all Integrity customers, including those where a permit may not be required, can be confident knowing their building will stand strong for decades.

Integrity stands by its product and its commitment to ensuring every building is built strong. “We offer an industry-leading warranty which includes a 5-year workmanship warranty and a lifetime warranty on Perma-Columns,” adds Jason. “Including a warranty on our buildings is not unique in the industry. However, ours is more robust and includes the whole building, not just the individual components.”

Integrity also leads the Western Canadian post-frame industry for its rigorous safety standards. “It’s important that our crews are safe, and our customer’s property is protected,” explains Jason. “Our crews follow rigid safety protocols, ensuring everyone who arrives in the morning leaves safely at the end of the day. Our drivers and construction crews all have the necessary training and licenses to ensure they operate equipment properly, and we work closely with our customers to ensure their property is not damaged.”

Beyond Products: The Integrity Approach

Integrity Post Structures is proud of its innovative products and services, but the Integrity Difference isn’t solely defined by these tangible offerings. It’s about the approach, the mindset, and the unwavering dedication to excellence. It’s a commitment to innovation, sustainability, and safety, with a focus on improving both the product and the process.

“The definition of Integrity is to always do the right thing, even when no one is looking. And not because you were told to, but because we want to,” explains Jerry. “We are committed to leaving the industry better than we found it. That’s the Integrity way.”