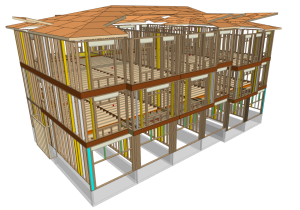

Large-scale multi-family building projects require a unique approach. Integrity Building Products is experienced with the specific challenges and demands facing multi-family builders in both pre-construction and during construction. To ensure budgets and deadlines are met, and framers get the materials on time, Integrity has formed a team of specialists focused on the multi-family segment. From proposals to design to budgets and the precise coordination of material deliveries, our collaborative approach ensures seamless execution in alignment with our client’s expectations and project timelines.

Customized Service: The Integrity Advantage

The key to our successful partnerships with multi-family builders is the customized service Integrity offers. “We know that multi-family projects have their own requirements and challenges and benefit from a different fulfillment strategy than single-family projects,” explains Scott Myer, Chief Operations Officer for the Integrity Group and business unit leader for Integrity Building Products. “To provide greater service to our multi-family customers, we have a dedicated team that focuses solely on this project type.”

Integrity also has a dedicated team of designers that focus solely on multi-family structures. “We are specialists in our field,” explains Mike Boon, Design and Estimating Manager. “We have a dedicated team of designers who are experienced and focused on multi-family projects. The benefits of having a specialized team are the team’s depth of knowledge and experience in multi-family, and the team’s processes and structure are focused on the unique requirements of a multi-family project.”

“We have found great success in our partnership with Integrity,” states Stephanie Shepherd, Development Manager at Slokker Homes. Integrity supplied the building materials for Slokker’s Elkwood townhome project in the community of Aspen Spring. “The Integrity team goes above and beyond, bringing forward new ideas and solutions. At Slokker we have a saying, ‘Practical Creativity’. It’s about bringing creative solutions and creative strategy forward while ensuring the action makes business and strategic sense. Integrity shares that value, they value innovation and they are willing to work with us on process and strategy to find new solutions to our challenges.”

Critical Planning & Communication

Multi-family projects are an intricate choreography. Compared to single-family builds, there are more moving parts, more stakeholders, and more opportunities for delays. Planning and communication is critical in managing and coordinating all of the moving parts. “We know that planning is the cornerstone of any successful multi-family project. It’s about anticipating every step – from coordinating with engineers and consultants to ensuring clear communication between internal teams and our clients,” explains Scott. “The Account Manager guides the process.”

The Account Manager is responsible for understanding the full scope of a project – timelines and material requirements. “I start working with our multi-family customers at the bid stage,” explains Jaret. “Gathering information so we understand the full scope and requirements of their project so that we can quote it with accuracy. Once a project is awarded, we begin onboarding the client and carefully planning the project timelines and all deliverables with precision.”

A keystone to Integrity’s process is the pre-planning phase, “The pre-planning phase is when we get to collaborate the most, focusing on all the many details required to build an accurate project plan and workback schedule,” explains Jaret. “It is at this stage that our design team reviews the client’s plans, identifies challenges, value-engineers solutions, and helps ensure everyone is on the same page and working towards the same goal.”

“When we began work with Integrity, their team patiently walked us through their pre-planning process,” explains Stephanie. “This was a new experience for us, no other supplier had done this with us before. We reviewed the plans and 3D models, discussed challenges in the design that the Integrity team identified and discussed their proposed solutions. They even included our trades in the review to ensure that installation of plumbing, mechanical and electrical systems would be seamless.”

Making the Transition to Prefabricated Wall Panels

Another ‘first’ for Slokker was framing with prefabricated wall panels. “We started looking into the possibility of using prefabricated wall panels in our townhome construction versus stick frame,” explains Stephanie. “We wanted to explore a different method to create a more efficient construction process.”

“Prefabricated wall panels are not as new for the multi-family segment as they are to single-family construction. However, not all builders, especially those building townhomes, have fully transitioned to them,” explains Jaret. “We worked with Slokker to design and implement prefabricated wall panels into their design and framing methods.”

“The team at Integrity made the transition to wall-panel construction so smooth,” adds Stephanie. “Their design team worked with our team to ensure the assembly details were accurate, and their field service team worked on-site with our framers to provide additional training. We felt very supported by the Integrity team in making this transition, and with their support, we are successfully building our townhomes using the prefabricated wall panels with minimal challenge. And the best part is the successful transition to wall-panel construction saved us money and minimized waste on site. It was a big win overall!”

A Team Approach

At Integrity, success in delivering products to our multi-family customers on time and within budget hinges on seamless teamwork. That team spans across departments and disciplines. “In our deliverables, the account manager, the design team, and our field support team get a lot of the glory. Behind the scenes our supply chain team, manufacturing teams, fulfillment and delivery teams are equally as responsible for our successes,” explains Scott.

“The supply team doesn’t always get the credit they deserve,” adds Jaret. “Multi-family construction requires pricing months in advance. Some clients prefer flexibility and are OK with fluctuations in commodity prices, while others want more stable pricing to align with their product strategy commitments. Depending on our client’s business needs, the supply team will adapt their buying strategy to provide the customer with the level of confidence they require.”

Building Success Together: Your Multi-Family Construction Partner

Successful multi-family construction requires not only quality products but also successful partnerships. Integrity’s unwavering commitment to our multi-family customers sets us apart. Through personalized service that is tailored specifically to the unique needs of each of our multi-family clients, our customers have confidence that they will receive their product, on time and on budget.